Polymer plate printing

On Saturday for the first time I printed from a polymer plate on the Vandercook at AS220 (part 2 of my 3-part class on letterpress printing). Students were asked to choose an image (black and white, with no shading), and to send it to a pre-press servicing company which produced the film. Here is the image I sent:

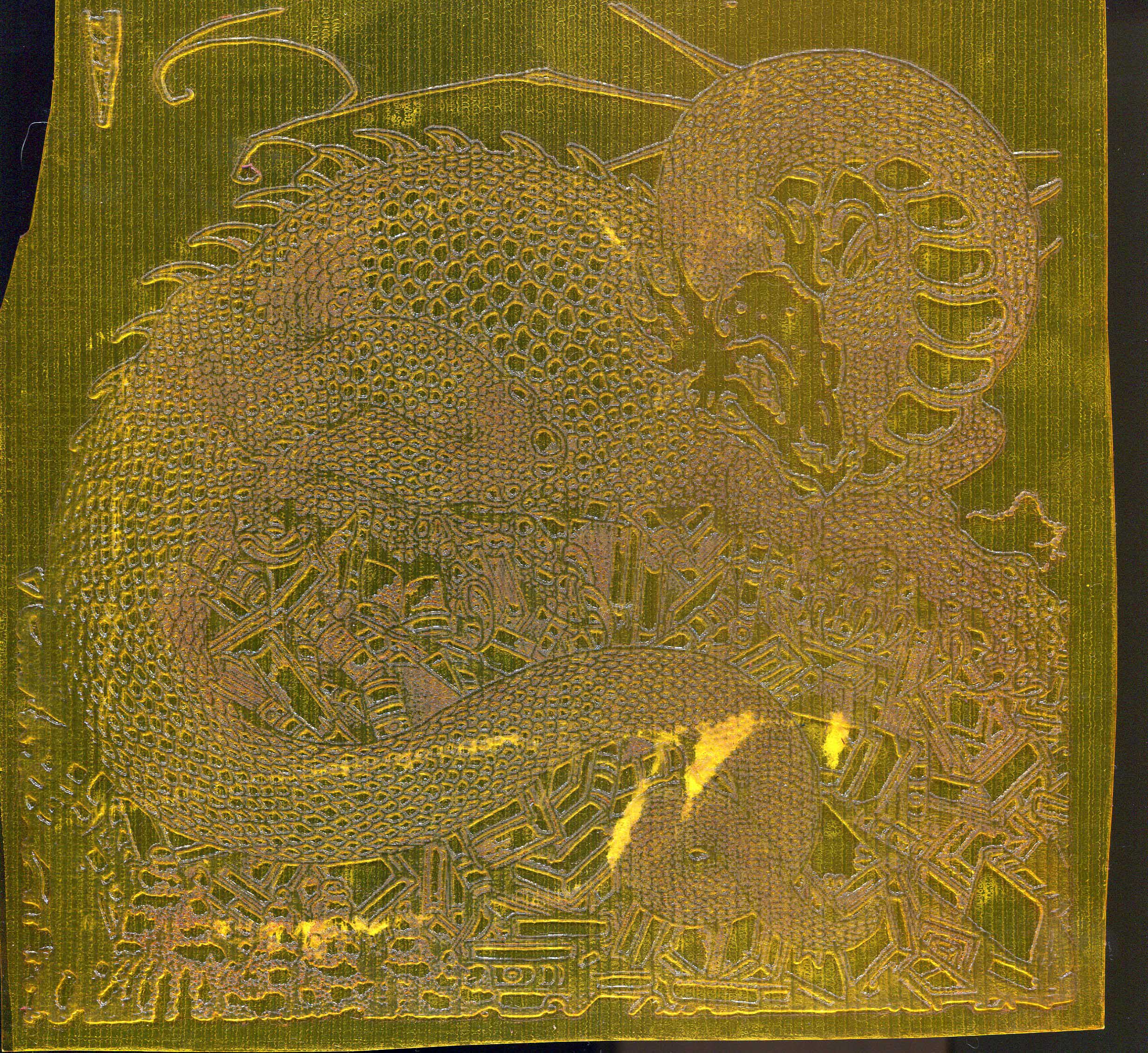

And here is the negative which was produced from it:

Then we placed the negative on top of a photo-sensitive polymer plate with a layer of backing, exposed it to fluorescent light for about 5 minutes to bake the image in, placed the plate in a warm water bath, lightly scrubbing “away” the film which was in the negative spaces with a flat, soft brush (mine took about fifteen minutes, since it was rather large, about 8 x 8 inches), and then used a hair dryer to finish the process. Here is what the plate looks like:

Once dry, you peel off a layer from the backing, to reveal an adhesive side. The white stuff you see here was a little bit of paper that got stuck (by mistake) to the backing. The reason for the adhesive is so that the plate does not move when you print (these are too flimsy to lock into a chase).

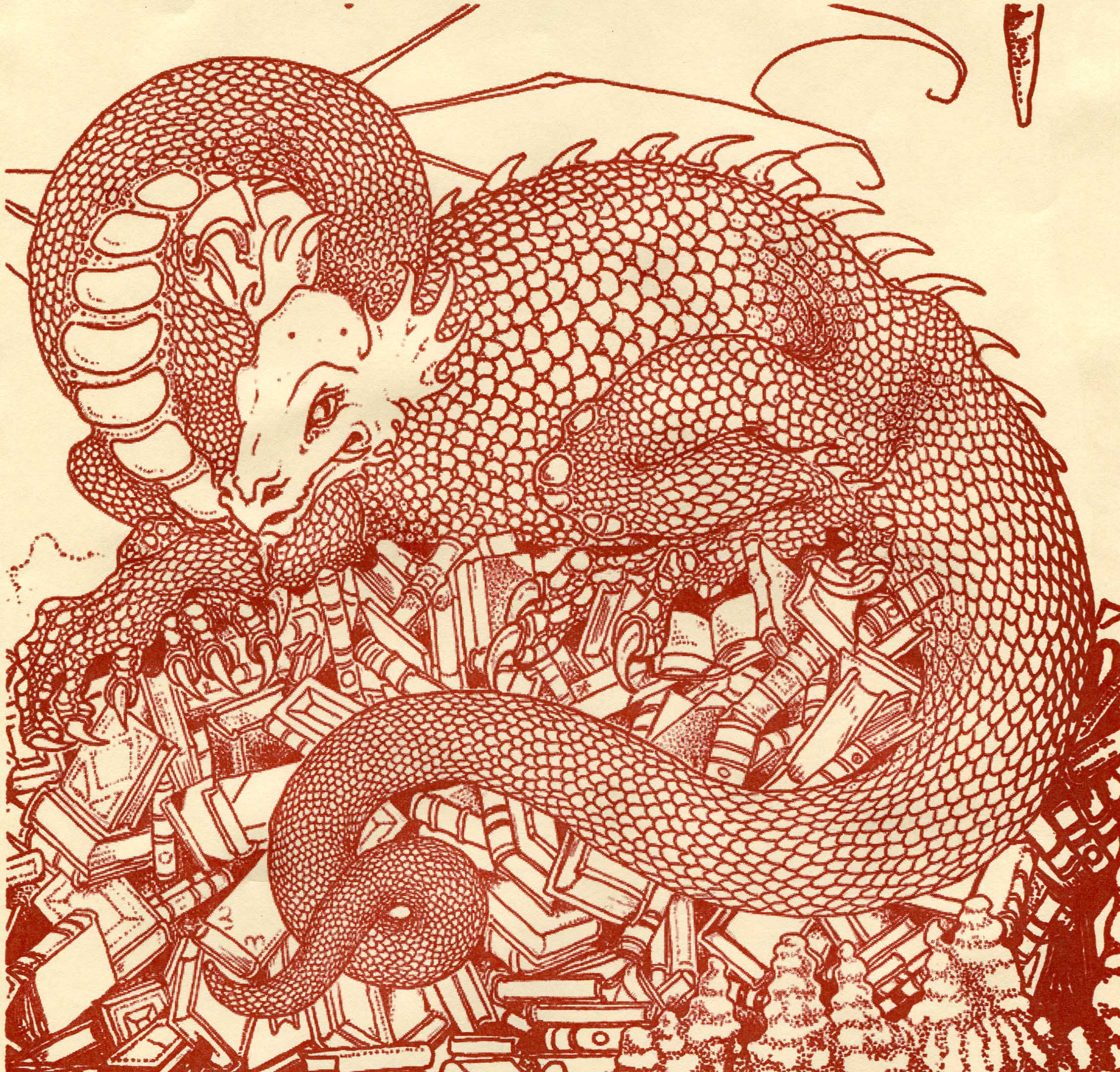

Using a precision-milled, flat block of steel which is locked into the bed of the press, and guided by a grid printed on its surface, we placed our plates, inked the rollers with a nice smoky red (red mixed with a little black), and ran our prints. Given the level of detail in mine, I think it turned out rather well for a first time effort:

Using a precision-milled, flat block of steel which is locked into the bed of the press, and guided by a grid printed on its surface, we placed our plates, inked the rollers with a nice smoky red (red mixed with a little black), and ran our prints. Given the level of detail in mine, I think it turned out rather well for a first time effort:

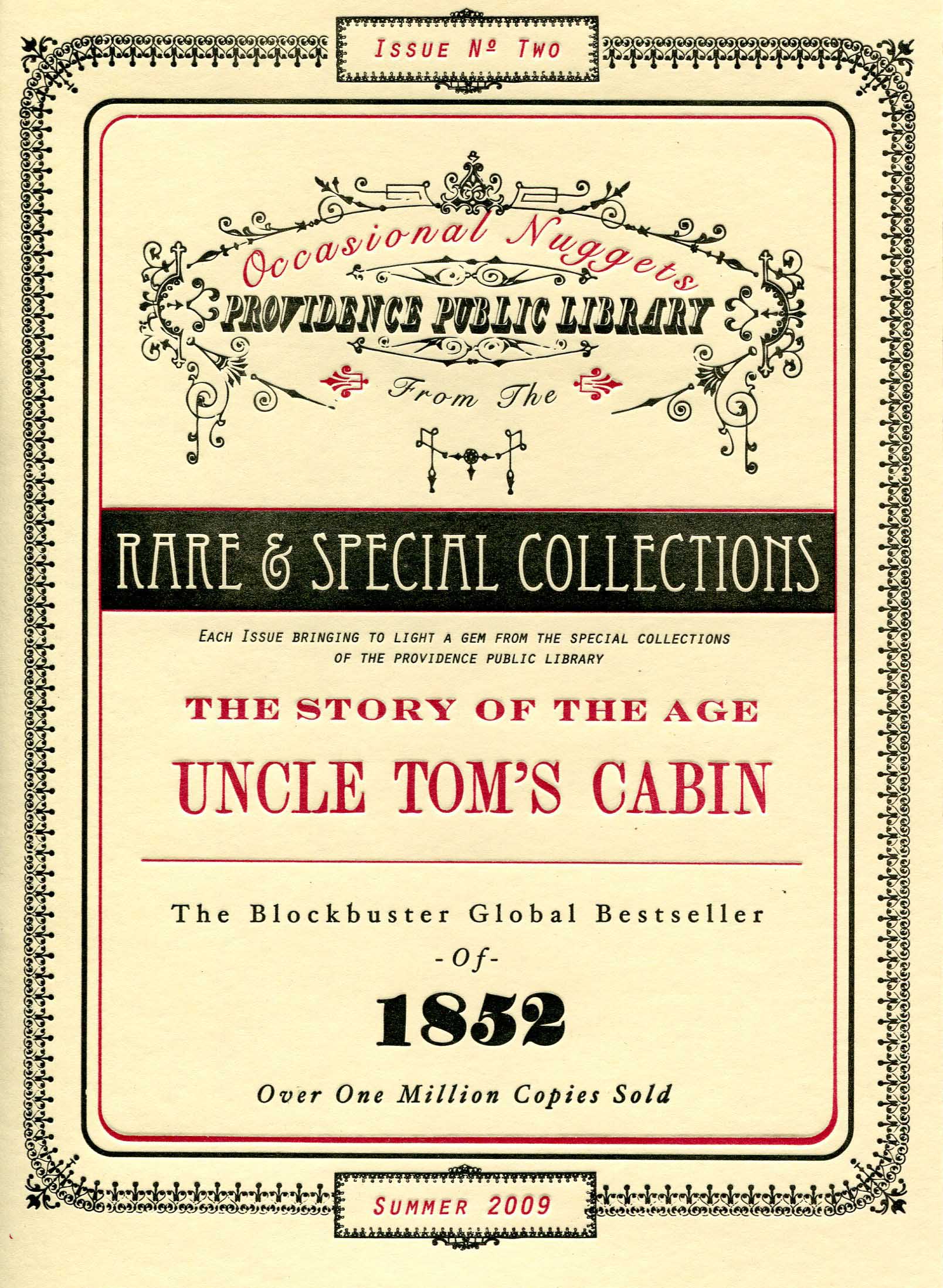

For printmakers, the possibilities are greatly multiplied if you have access to this process. This holds true for makers of books as well, of course. In fact, it was this process which made it possible for me to issue a quarterly series while in my previous position. The following cover was produced from polymer plates, which were created by scanning 19th-century type ornaments from specimen books, incorporating them into a computer-generated design, and producing negatives of that design:

Tags: Washington Press